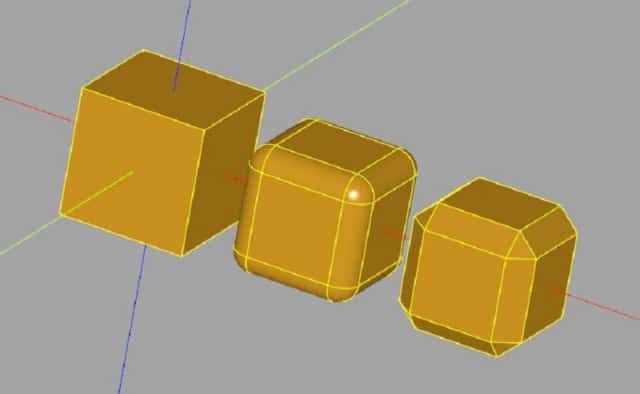

A fillet is a rounded edge, while a chamfer is a beveled or angled edge. Fillets are generally used to smooth the transition between two surfaces, while chamfers are used to create a 90-degree corner. When creating 3D models or mechanical drawings, fillets and chamfers can be used to give objects a more finished look. Fillets and chamfers can be applied to both inside and outside corners.

Also, Fillet and chamfer are two different types of machining techniques that are commonly used in mechanical engineering projects. Both fillet and chamfer operations help strengthen the load-bearing capacity of your design, but they have significant differences that you need to understand before making your final choice. Here’s what you need to know about each type of joint before deciding which one to use in your next project.

Table of Contents

What are Fillet and Chamfer

A fillet is a rounding of an interior or exterior corner of a component or part in mechanical engineering. The fillets are concave at the inlet and convex at the outer or exterior corners. Fillets are used by engineers to counteract mechanical loads and prevent rapid deformation at the part’s margins.

Chamfers, on the other hand, are an antonym of the fillet and are used to substitute a sharp corner or angled corners of a design or item (typically at 45° or 60°). It provides the rough edge with a more consistent appearance. Fillets and chamfers both improve the appearance of a part. Chamfered edges, on the other hand, are more forgiving now that they are in line with production patterns; you can simply incorporate them into attractive designs.

Things to keep in mind when creating Fillet and Chamfer

Bottomed Edges CNC Machining

We have a cuboid portion with an inner (or concave) and exterior (or convex) fillet in a cavity.

Bottomed edges (concave fillet) like these are particularly difficult to produce with CNC machines because they necessitate the use of specialized tools such as ball end mills. Ball end mills are delicate and are employed at slower cutting rates, thus not only will this increase your production expenses, but it will also likely add to your lead time. As a result, square-bottom features might be a preferable choice.

However, if the functionality of your design necessitates fillets at the bottom borders, you should consider creating your item using the additive 3D printing procedure.

Fillets should be designed on the internal edges of vertical walls

CNC milling’s subtractive nature results in rounded corners (or fillets) between a cavity’s vertical sides.

The size of these fillets is determined by the end mill tool size utilized in the milling procedure. For example, a 0.8 mm end mill tool may produce fillets with a radius of 0.4 mm. So, if you want to use this end mill tool to make a cavity, you won’t be able to make a fillet with a radius of 0.2 mm. When creating fillets where a vertical wall meets a horizontal wall, you must additionally take end mill tool size into mind.

Fillet and chamfer size determination

The fillets and chamfer are generally applied as per required fitting sizes of mating parts or as per requirements. But the general principle for deciding fillet and chamfer is defined in ISO and ASME Rules. The tools selected for machining must fulfill the required targets defined in these rules.

Application of Fillet and Chamfer

Although both (fillet and chamfer) are different, they play a vital role in our everyday applications. They are used no longer solely in mechanical engineering but also use in people’s livelihood fields and are involved in the daily application of fillets and chamfering.

- The turning tool is about 15 cm long, with a zigzag shape on the sides and a sharp edge on the top, which is a chamfer. Chamfering is a technique for sharpening the edges of turning tools. It can be installed on ordinary lathes to manufacture various parts, such as stepped shafts, plums then gaunt shafts.

- From the evaluation of the watch alone, due to the fact the watch is worn on the wrist, the chamfer will scratch the skin, which incorporates a greater risk. The fillets tend to be rounded and smooth, which improves the protection of wearing.

- In everyday life, primarily different types of tables are used, such as coffee tables, writing desks, pool tables, consoles, and many more. Fillet or chamfer are decided by extraordinary situations and desires. Take the coffee table as an example. At present, whether or not the coffee table is quadrilateral or round, the method of chamfer + fillet is adopted. The edge has a 45° bevel, and the sharp edges produce fillets after two sharp edges are generated.

- Chamfers are used on the edges of furniture like counters and tabletops to prevent individuals from injuring themselves on the sharp corners. Bullnose refers to when the edges are rounded rather than square. Chamfer mills and chamfer planes are some of the tools that are employed.

- The fillets have extensive use in all engineering manufacturing products like Nut-Bolts to shafts, rotating mechanisms, gear terrains, automotive, aerospace parts, turbines and domestic products.

Conclusion

Both fillets and chamfers are an important aspect of mechanical engineering. They are used to reduce stress concentration factors, decrease friction, increase bearing surface area, protect corners from wear, etc. However, a chamfer can be much more forgiving than a fillet since it has two bearing surfaces while a fillet only has one. Regardless of which one you choose to use; both are incredibly beneficial to mechanical engineering. The stress concentration is always damaging the sharp edges, due chamfer and fillets the stress concentration and strained areas have less effect, so the part remains at higher performing end. While higher speed rotating components have higher effect of wear and tear, so these two techniques are going to make the higher life of these rotating parts by giving less frictional effects. The design which has fillets and chamfer creates look and higher engineering performance prospect for user and profitable in longer run.